Automobile Sectors Mostly Used Which Type of Coating Method

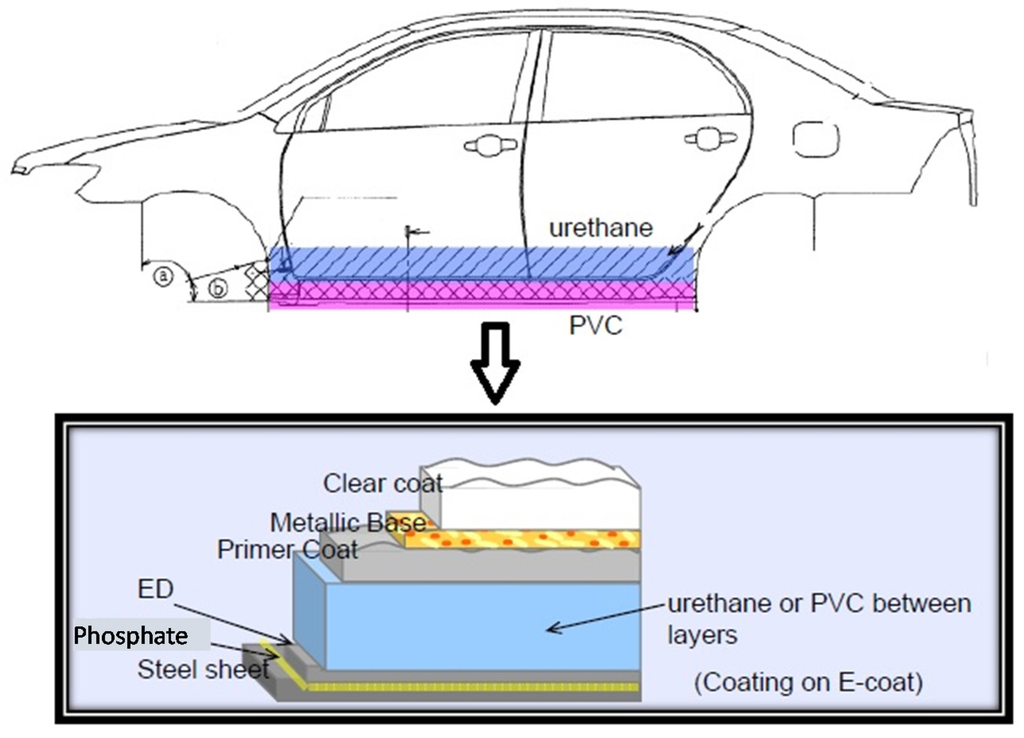

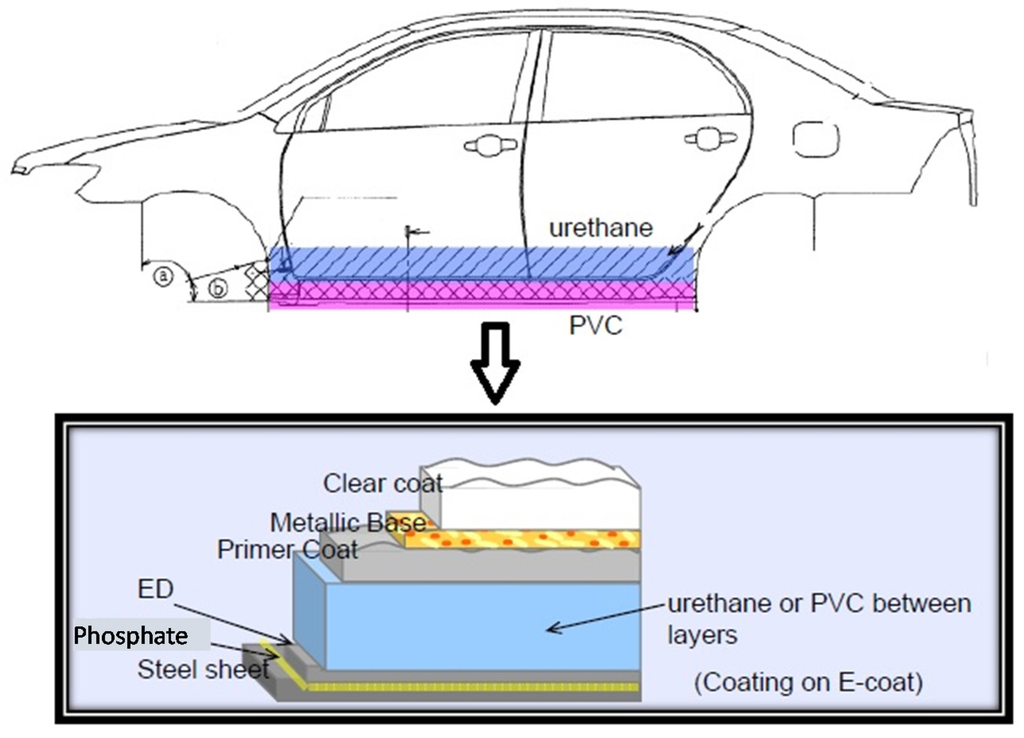

Both a galvanic and a polymeric barrier. The process of applying a basecoat color and then clearcoating is known as a two stage or basecoat clearcoat process.

Coatings Free Full Text Evolution Of The Automotive Body Coating Process A Review Html

They make great adhesion-promoting primers.

. Such as cycles type writers etc. Paint application requires preparation. Battery-heavy and electric vehicle coatings require the lightweighting that aluminum and magnesium offer while still benefiting from corrosion protection and the excellent base they establish for adhesives and paints he says.

Modern automobile paint is applied in several layers with a total thickness of around 100 µm01mm. In big industries like automobile each department is producing independently one or more components. Electro-ceramic coatings zirconium coatings and titanium bases.

It is an alternative to. Although the basic transfer process involves a two-coat operation the top and the tie coat a three-coat process is becoming quite popular. Future steps towards the realisation of a low-carbon automotive sector are discussed.

For the automotive industry spray coating is achieved by using either air spray guns or high-speed rotary bell atomizers both of which can be either electrostatic or non-electrostatic. Included in the Automotive Sectors are NAICS 336 Transportation Equipment Manufacturing NAICS 4231 Motor Vehicle and Motor Vehicle Parts and Supplies Merchant Wholesalers and NAICS 8111 Automotive Repair and Maintenance. Therefore the classification of coating techniques can be very complicated.

From late 1950s to 1980s acrylic lacquer was the most sought-after automobile paint and it was mostly on luxury and expensive vehicles like Rolls Royce. Water-based acrylic polyurethane enamel paint is currently the most widely used paint for reasons including reducing paints environmental impact. The first coat is typically called the primer or undercoat and the final layers are called topcoats.

Automotive Coatings Market Analysis By Product Primer Electrocoat Basecoat Clearcoat By Technology Waterborne Solventborne Powder Coating UV-Cured By Application Metal Plastic By End-Use And Segment Forecasts 2018 - 2025. Dry particulate solids commonly called powder coatings. Zinc coatings are particularly effective when used on steel and provide dual function corrosion protection.

To complement such cars. Transfer coating is used for PVC pastes and for PU coating. Cover containers used during spray coating operations to prevent solvent volatilization.

The range of materials used in automobile engine components is extensive indeed. Use water-based coatings and lacquer finishes to decrease volatile organic air emissions. How to Make Coating Emissions Management Accurate and Simple.

Install automated spray systems which adjust spray angle for each hide and reduce overspray. Industries and facilities in these sectors engage motor vehicle manufacturing sales and salvage and repair and. Energy efficiency and thermal management practice are highlighted.

The Automotive Industry consists of a broad range of organizations and companies with a critical objective of designing developing marketing manufacturing and selling of motor vehicles. Three types of lightweight coating pretreatments are available according to Coggins. Automatic spray coating requires the use of robots and as such automatic coating is sometimes referred to as robotic coating.

The industry also does not include. The paint shop is reviewed focusing on components paints and energy utilisation. Gloss and appearance of the painted system.

Where Are Ceramic Coatings Most Used In The Automotive Industry. The first two heads apply the top coat in two thin layers. Currently the automotive industry uses powder coating on.

Vehicle manufacturing process is described focusing on the energy sources and use. Different vehicles and machinery are used for a wide variety of activities such as recreation construction or agriculture and finding a durable. Regardless of the coating formulation or number of layers applied proper part preparation application techniques and curing processes are necessary for the desired coating characteristics to be achieved.

During electroplating both metals are placed in an electrolytic solution. Take a look at four of the different types of industrial paint coatings that are offered by Midwest Industrial Coatings Inc. Since one of the greatest challenges in sustainability for the automotive sector is being able to quantify and measure sustainability projects most manufacturers have turned to some form of sustainability software that can assist with their goals.

Acrylic coatings have many advantages including quick-drying and high gloss capability. The automotive industry makes a vital part of the worlds economic sectors by revenue Automobiles however are not entirely included in the industry. The top 5 automotive refinish coatings vendors are Axalta AkzoNobel BASF PPG and Sherwin-Williams.

Basecoats also known as base or base color are a class of automotive paints that require a clear coating to achieve the final. Ceramic coating This is a type of paint protection coating which uses nanotechnology to protect a vehicles paintwork from damage from UV radiation as well as maintaining its gloss and repelling dirt and water. These surface coating methods can be applied for different requirements of applications.

However the most common surface coating methods can be classified as below. The metal to be coated acts as the anode while the coating metal acts as the cathode. Electroplating also known as electrodeposition involves depositing a thin layer of one metal on the surface of another metal.

This method is utilized by firms which manufacture variety of standardized products having no relation to one another in cost quality and the type of process etc. Automotive paint is paint used on automobiles for both protection and decoration purposes. Heat is either dispersed or absorbed thanks to some of the properties involved in the materials utilized in the mechanics so temperatures can fluctuate significantly.

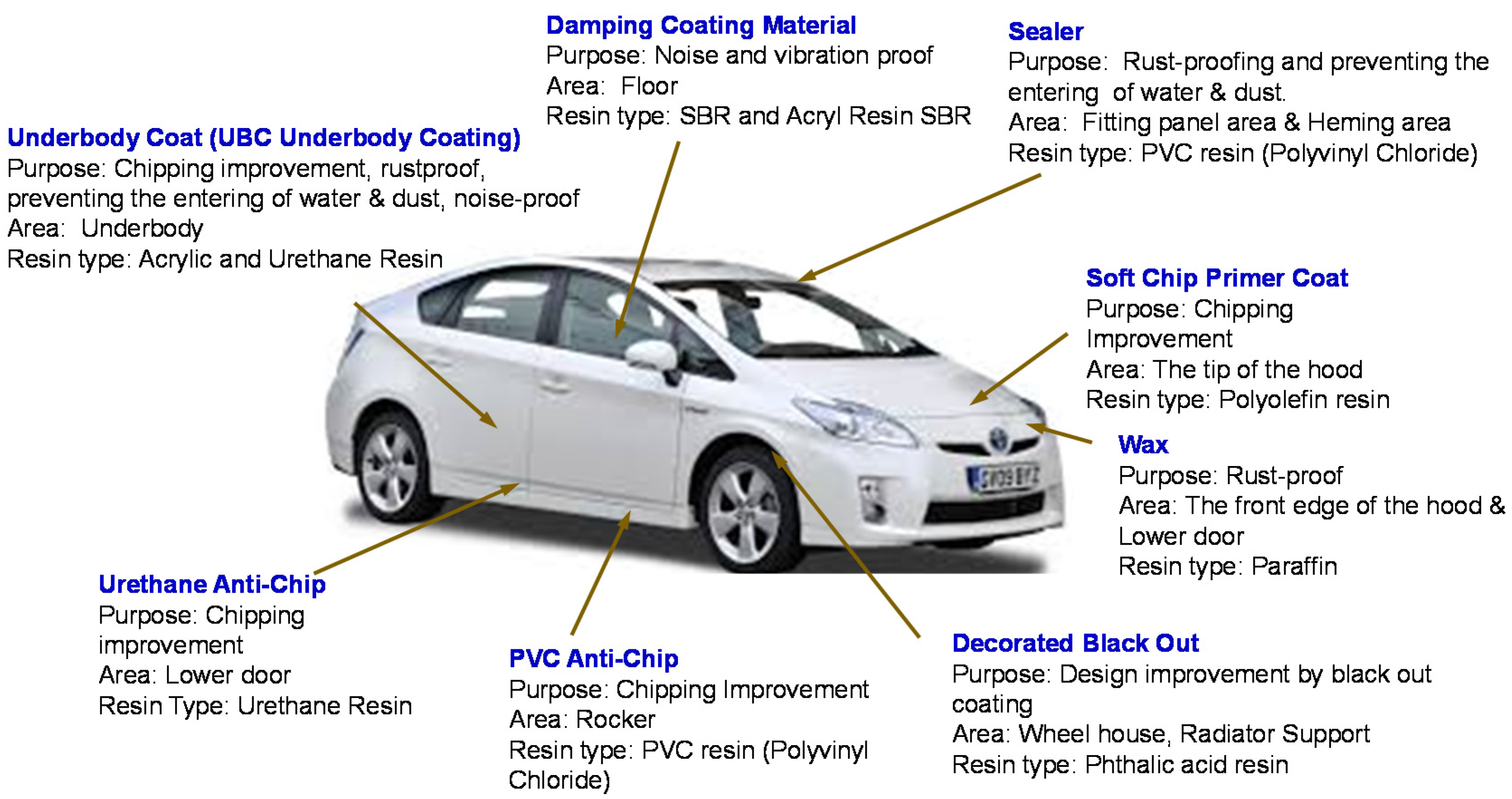

Zinc-rich coatings are durable and resist abrasion. Their compositions contain very low concentrations of volatile solvents on the order of 2 substanstially less than any other paint system. Automotive coating is type of coating where vehicle parts are coated with some liquids or powders to enhance the toughnesscolour lockin case of outer partsheat or shock resistancein case of inner parts or for various enhancement of the vehicle surface There are 2 types of coating.

Solvent based paints make for a heavy-duty color coating on your automotive equipment. Prepare smaller test batches of solvents and coatings.

Schematic Of A Typical Four Layer Automotive Coating System Download Scientific Diagram

Coatings Free Full Text Evolution Of The Automotive Body Coating Process A Review Html

Schematic Of A Typical Four Layer Automotive Coating System Download Scientific Diagram

No comments for "Automobile Sectors Mostly Used Which Type of Coating Method"

Post a Comment